The Art and Engineering of Color-Coated Steel Wire Rope: A Comprehensive Guide

Chapter 1: The Evolution from Bare to Beautiful

**Historical Context: The Birth of Wire Rope**

The development of steel wire rope dates back to the early 19th century when German mining engineer Wilhelm Albert created the first recognizable wire rope in 1834. For over a century, wire rope remained primarily functional, with corrosion protection limited to galvanization or occasional painting. The concept of applying durable, colored coatings emerged in the mid-20th century as architects and designers began seeking materials that could perform structurally while contributing aesthetically to built environments.

**The Aesthetic Revolution in Industrial Materials**

The postmodern architectural movement of the 1970s and 80s challenged the notion that structural elements should be hidden. Architects like Richard Rogers and Renzo Piano celebrated mechanical systems, creating a demand for industrial components that were visually intentional rather than merely functional. This cultural shift created the market for color-coated wire ropes, transforming them from hidden components to design features.

## Chapter 2: Manufacturing Process: From Steel to Spectrum

**Raw Material Selection: The Core of Strength**

The journey begins with high-quality steel wire, typically composed of:

- High-carbon steel (0.60-0.95% carbon) for maximum strength

- Stainless steel (AISI 304 or 316) for corrosive environments

- Extra-high-strength alloys for specialized applications

Wire drawing reduces steel rods to precise diameters through a series of dies, creating the individual wires that will form strands.

**Strand Formation and Rope Construction**

Wires are twisted into strands, which are then helically laid around a core to form the rope. Common constructions include:

- 6x19 (6 strands with 19 wires each): General purpose with good flexibility

- 6x36: More flexible with finer wires

- 7x7 and 7x19: Aircraft cables with high flexibility

- 1x19: Single strand construction for minimal stretch

**Pre-Treatment: Ensuring Adhesion**

Before coating, the bare wire rope undergoes critical preparation:

1. **Chemical cleaning**: Removal of oils, drawing compounds, and surface contaminants

2. **Abrasive blasting**: Creation of a surface profile for mechanical adhesion

3. **Phosphating or conversion coating**: Chemical treatment enhancing corrosion protection and paint adhesion

4. **Primer application**: Epoxy-based primer ensures optimal bonding

**Coating Application: The Color Transformation**

Modern coating methods include:

**Extrusion Coating**

The most common method for PVC, polyurethane, and nylon coatings:

- Pre-heated rope passes through cross-head extruder

- Molten polymer forms continuous, uniform sheath

- Precise temperature control ensures adhesion without compromising steel temper

- Water bath cooling sets the coating

- Capable of applying multiple layers (primer, color, protective topcoat)

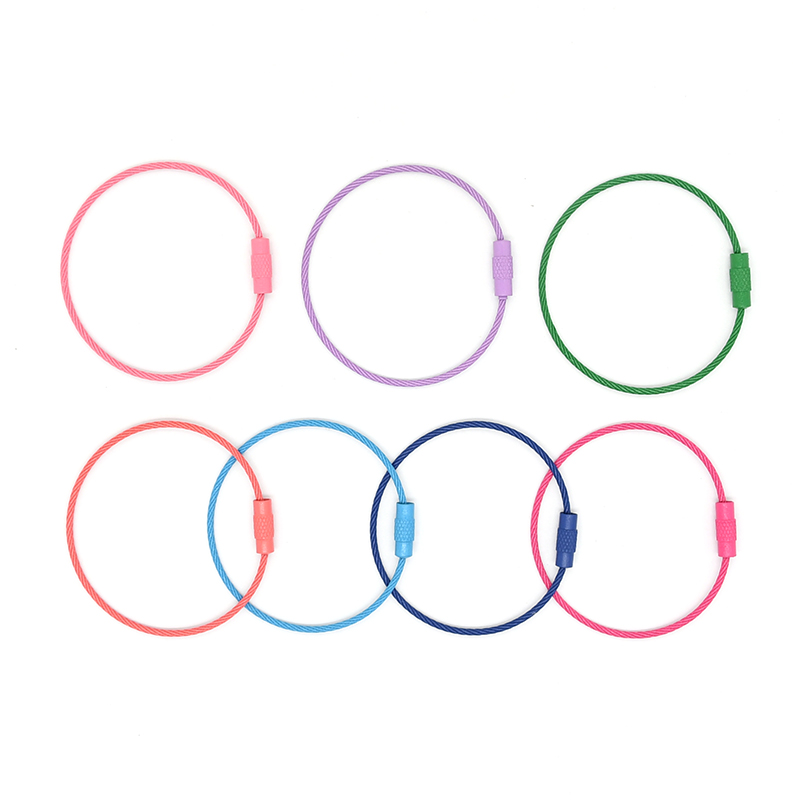

**Color Matching and Customization**

Advanced manufacturers offer:

- Standard RAL color matching

- Custom color formulation

- Dual-color coding for identification

## Chapter 3: Technical Specifications and Performance Characteristics

**Mechanical Properties: Maintaining Core Strength**

Contrary to aesthetic appearance, color-coated wire ropes maintain exceptional mechanical properties:

**Strength Retention**

High-quality coatings add minimal diameter (typically 0.5-2.0 mm) while preserving:

- 90-98% of bare rope breaking strength

- Full flexibility and bend radius capabilities

- Fatigue resistance comparable to bare ropes

**Diameter and Weight Considerations**

Coating adds approximately:

- 5-15% to diameter depending on coating thickness

- 10-25% to weight per linear foot/meter

- Manufacturers provide detailed specifications for engineering calculations

**Environmental Performance**

**Corrosion Protection**

Multi-layer defense system:

1. **Galvanized or stainless core**: Primary corrosion resistance

2. **Primer layer**: Additional barrier protection

3. **Colored coating**: Seals against moisture and chemicals

4. **Topcoat (optional)**: UV and abrasion protection

Comparison of corrosion resistance:

- **PVC-coated**: Excellent resistance to acids, alkalis, salt water

- **Polyurethane**: Superior abrasion resistance, good chemical resistance

- **Nylon**: Excellent impact resistance, good chemical resistance

- **Polyethylene**: Good moisture resistance, economical

**Temperature Ranges**

Operational limits vary by coating:

- PVC: -10°C to +60°C (flexible range)

- Polyurethane: -40°C to +90°C

- Nylon: -40°C to +100°C

- Special formulations available for extreme temperatures

## Chapter 4: Applications Across Industries

**Architecture and Construction: The Visible Structure**

**Building Facades and Tensile Structures**

- Sun shading systems and brise-soleil

- Tensile membrane support cables

- Glass curtain wall stabilization

- Cable net facades (ex: Munich Airport, Allianz Arena)

**Bridge Applications**

- Suspended walkways and pedestrian bridges

- Railing infill with color-coded safety systems

- Aesthetic elements on structural cables

- Temporary bridge installations with high visibility

**Interior Design**

- Stair railings and balustrades

- Suspended ceiling systems

- Retail display systems

- Museum and exhibition installations

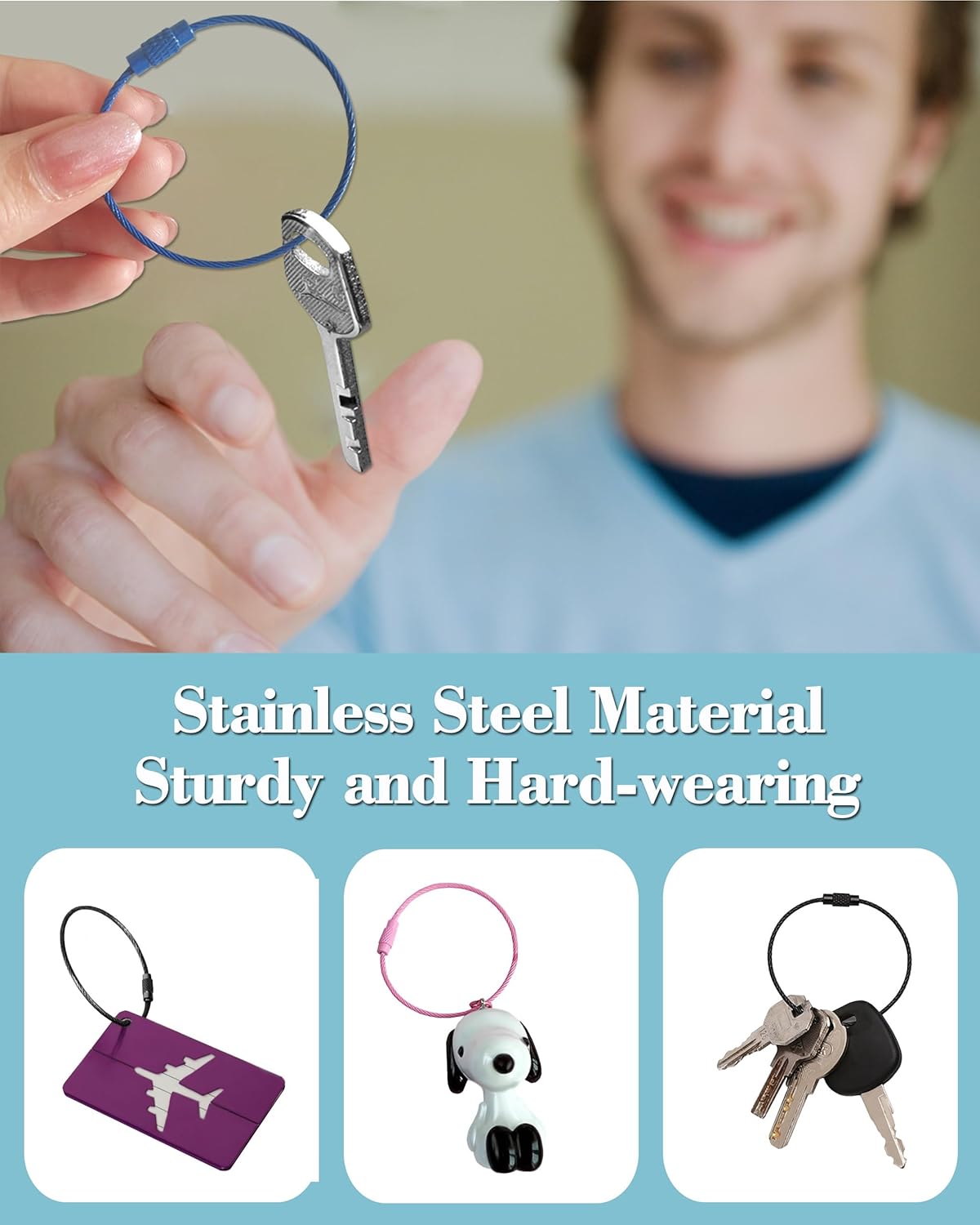

**Marine and Offshore: Corrosion Meets Color**

**Yacht Rigging and Marine Architecture**

- Colored standing rigging for sailboats

- Lifeline systems with high visibility

- Dock and marina applications

- Naval architecture with customized colors

**Offshore and Coastal Engineering**

- Marker buoys and navigation aids

- Safety systems on platforms

- Aquaculture and fish farming installations

- Research installations requiring identification

**Industrial and Material Handling**

**Cranes and Lifting Equipment**

- Color-coded crane cables for load identification

- Overhead crane installations

- Safety yellow for visibility in warehouses

- Theater and stage rigging

**Conveyor Systems**

- Guide lines and safety boundaries

- Product identification in automated systems

- Food processing applications with FDA-approved coatings

**Agriculture and Forestry**

- Vineyard trellising with color-coded systems

- Greenhouse structures

- Safety boundaries in agricultural equipment

- Logging and forestry applications

**Transportation and Automotive**

**Aircraft and Aerospace**

- Control cables with color identification

- Interior components

- Ground support equipment

- Museum displays of aircraft

**Automotive Testing and Assembly**

- Safety barriers in testing facilities

- Assembly line guidance systems

- Color-coded systems for different vehicle models

**Arts, Entertainment, and Retail**

**Stage and Theater**

- Rigging for lighting and scenery

- Safety lines with low visibility colors

- Temporary installations for events

- Museum exhibition supports

**Retail and Display**

- Product display systems

- Temporary exhibition structures

- Window display installations

- Trade show booth construction

**Public Art and Installations**

- Sculptural installations

- Public space interventions

- Temporary festival structures

- Interactive art installations

## Chapter 5: Design Considerations and Selection Criteria

**Color Selection: Beyond Aesthetics**

**Functional Color Coding**

- Safety yellow for hazard areas

- Green for safety equipment

- Red for emergency systems

- Blue for potable water applications

- Custom coding for complex systems

**Architectural Integration**

- Matching corporate colors

- Complementary colors for structures

- Contrast for visual interest

- Camouflage for minimal visual impact

**Environmental Considerations**

- Light colors for heat reflection

- Dark colors for UV absorption (in specific applications)

- Colors that minimize bird strikes (avian safety)

**Coating Thickness: Balancing Protection and Flexibility**

**Standard Thickness Ranges**

- Light duty: 0.3-0.5 mm (interior, minimal abrasion)

- Medium duty: 0.5-1.0 mm (general purpose, outdoor)

- Heavy duty: 1.0-2.0 mm (high abrasion, harsh environments)

- Extra heavy: 2.0-3.0 mm (extreme conditions, offshore)

**Impact on Minimum Bend Radius**

General rule: Minimum bend radius = 6-8 x coated rope diameter

Thicker coatings may require larger bend radii to prevent cracking

**Load Capacity and Safety Factors**

**Calculation Considerations**

- Coating adds minimal strength (primarily protective)

- Core rope specifications determine breaking strength

- Temperature effects on coating flexibility

- Dynamic vs. static loading considerations

**Safety Factors by Application**

- General lifting: 5:1 minimum safety factor

- Personnel lifting: 10:1 minimum safety factor

- Permanent installations: 3.5-4:1 typical

- Temporary installations: 2-3:1 (with engineering approval)

## Conclusion: The Future is Colorful and Strong

Color-coated steel wire rope represents a remarkable synthesis of engineering precision and design sensibility. What began as simple protection for steel cables has evolved into a sophisticated product category that serves industries ranging from architecture to aerospace, from marine engineering to public art.

The continued development of coating technologies promises even greater performance—longer lifespans, smarter functionalities, and more sustainable production methods. As architects and engineers increasingly seek materials that perform multiple roles—structural, protective, aesthetic, and even sensory—color-coated wire ropes will undoubtedly play an expanding role in our built environment.